When the lights go out, your critical operations can't afford to go with them. That's where a reliable standby generator steps in, a silent guardian waiting to restore power the moment the grid falters. But this isn't a "set it and forget it" piece of equipment. Without diligent Preventative Maintenance and Safety for Critical Generators, that guardian can become a costly liability, leaving you in the dark when you need it most.

Imagine a hospital without power, critical systems failing. Or a data center suddenly offline, millions lost in an instant. These aren't just inconveniences; they're potential disasters. The secret to avoiding such scenarios? A robust, well-executed plan for maintaining your generator and ensuring its safe operation.

At a Glance: Keeping Your Critical Generator Ready

- Generators aren't "install and forget": Regular checks are vital for reliability.

- Preventative maintenance saves money: It extends life and prevents costly emergency repairs.

- Safety is non-negotiable: Improper operation risks carbon monoxide, electrical hazards, and fire.

- Follow manufacturer guidelines: They're your primary source of truth for maintenance.

- Document everything: A logbook tracks performance and identifies trends.

- Load testing is crucial: It ensures your generator can handle real-world demands.

- Professional help is key: Many tasks require trained, qualified personnel.

The Unseen Guardian: Why Your Generator Needs Constant Care

Your standby generator is a sophisticated, self-contained power plant, ready to kick in when the primary electrical grid fails. Unlike an emergency generator, which specifically serves life-health-safety loads and is often code-required (think hospital operating rooms), a commercial standby generator (often categorized as NFPA 110 Level 2) handles less critical, though still essential, operations. This might include business continuity, communication systems, or security infrastructure.

These systems are designed for limited, not extended, use. Whether powered by diesel, propane, natural gas, or gasoline, they consist of an internal combustion engine coupled with an electric generator. An Automatic Transfer Switch (ATS) acts as the brain, signaling the generator to start when grid power drops and stop when it returns. This intricate dance requires every component to be in peak condition.

Neglecting your generator's upkeep isn't just a gamble; it's a guaranteed path to premature failure, costly repairs, inefficient operation, and, worst of all, failure to start during an actual power outage. The difference between a minor hiccup and a full-blown crisis often boils down to the quality of your preventative maintenance program.

The Heart of the System: Key Components at a Glance

To truly appreciate the need for maintenance, it helps to understand what you're maintaining. A typical engine-driven standby generator is a symphony of interconnected parts:

- Engine: The powerhouse, converting fuel into mechanical energy.

- Generator (Alternator): Transforms mechanical energy into usable electricity.

- Fuel Supply System: The tank, lines, pump, filter, and injectors that deliver the generator's lifeblood.

- Lubrication System: Circulates oil to minimize friction and wear, keeping components running smoothly.

- Cooling System: A pump, fluid, radiator, and fan work together to dissipate the immense heat generated by the engine.

- Starting System: The electric motor and control logic that brings the engine to life.

- Exhaust System: Directs and often treats harmful exhaust gases safely away from the generator.

- Control Panel: The generator's dashboard, displaying vital parameters like oil pressure, coolant temperature, current, voltage, and frequency, and allowing for operational control.

- Air Intake System: Filters and delivers clean air for combustion.

- Batteries & Charger: Provide the initial jolt to start the engine and maintain their charge for readiness.

All these elements are managed by a system controller, often housed within an enclosure or dedicated facility. Each component, if neglected, presents a potential point of failure.

Navigating the Rules: Standards and Safety Mandates

Operating a critical generator isn't just about functionality; it's about compliance and safety. Federal, state, and local regulations govern everything from installation permitting to emissions certification and periodic inspections. Environmental stewardship is also a significant concern, especially regarding fuel storage and exhaust.

NFPA 110: Your Guiding Star

The National Fire Protection Association (NFPA) 110 Standard for Emergency and Standby Power Systems is the definitive guide. It sets forth stringent requirements for generator installation, maintenance, and testing. While our focus is on commercial standby (Level 2) systems, understanding NFPA 110's emphasis on reliability is paramount. Adhering to these standards, along with manufacturer guidelines and local building codes, isn't optional; it's foundational for safe and reliable operation.

The Blueprint for Reliability: Your Preventative Maintenance Program

A well-structured preventative and predictive maintenance program is the cornerstone of generator reliability. It's designed to catch minor issues before they escalate into major failures, extending your generator's operating life and protecting your asset investment. Think of it as a personalized health plan for your power backup.

Maintenance activities should always be conducted by trained, qualified personnel. Beyond the immediate repair, every task, every inspection, and every run hour needs to be meticulously logged. This documentation is invaluable for trend analysis, allowing you to anticipate future needs and optimize your maintenance schedule. Always prioritize manufacturer recommendations above all else.

The Rhythms of Readiness: Maintenance Frequencies

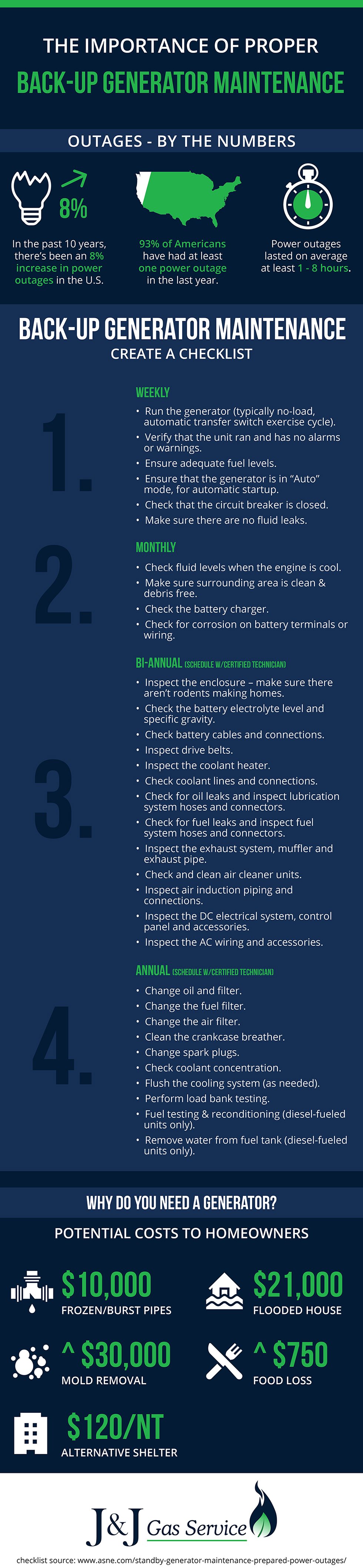

Effective maintenance isn't a one-time event; it's a continuous cycle. Here's a breakdown of recommended frequencies, using a diesel generator as a typical example:

- Weekly Walks and Checks:

- Run the generator for several minutes with no load.

- Verify control panel function and check for active alarms.

- Conduct a thorough visual inspection for debris, leaks, or loose components in the engine, radiator, and generator areas.

- Check fuel levels and, if present, drain any water from the fuel filter bowl.

- Inspect hoses and belts for wear or damage.

- Verify the engine block heater is operational (important in colder climates).

- Ensure the control panel is set to "Auto" mode.

- Observe visible exhaust emissions for any unusual smoke.

- Check the main circuit breaker to ensure it's in the correct position.

- Monthly Deep Dives:

- Check engine oil and coolant levels.

- Inspect the lubrication system for any signs of leakage.

- Bi-Annual Tune-ups:

- Take an oil sample for laboratory analysis (identifies wear metals, fuel dilution, etc.).

- Inspect coolant lines for integrity.

- Clean battery connections and apply corrosion inhibitor.

- Check connections at the starter motor and battery charger.

- Inspect battery electrolyte level and specific gravity (for flooded batteries).

- Clean the crankcase breather.

- Inspect the exhaust system, muffler, and piping for leaks or damage.

- Clean electrical boxes and control panels; inspect wiring for wear or loose connections.

- Inspect the air intake system and replace the air filter if needed.

- Annual Performance Reviews:

- Load Testing: This is critical. Run the generator for at least 1 hour under a full building load (ATS-initiated) or perform a load bank test. Record all operating parameters during this test. This simulates real-world conditions and identifies weaknesses before an actual outage. A significant incident involving a Philadelphia Comcast generator backfire highlighted the importance of proper system testing and maintenance, reinforcing how complex these systems can be under operational stress.

- Inspect the fuel tank for damage or corrosion.

- Verify emergency vent components on the fuel tank.

- Replace fuel filter(s).

- Inspect and replace fuel hoses if necessary.

- Grease generator bearings if applicable.

- Replace engine oil and oil filter (often guided by oil sample results).

- Inspect and replace engine oil hoses if needed.

- Check coolant condition using a test kit or strips, replacing the coolant if its protective properties are degraded.

- Inspect and adjust drive belts.

- Verify the engine block heater's functionality.

- Check and replace the radiator cap if faulty.

- Clean the radiator exterior to ensure efficient heat dissipation.

- Inspect the cooling fan shroud and all related system components.

- Inspect and clean the engine speed timing sensor.

- Inspect and clean ATS contacts and wiring.

Essential Tasks for Uninterrupted Power

While the above checklist is comprehensive, certain tasks are so fundamental they deserve special emphasis:

- Oil and Filter Changes: The Engine's Lifeline. Regular oil changes prevent contamination, reduce friction, and dissipate heat. Clean oil and filters are crucial to prevent premature engine wear and overheating.

- Battery Health: The First Spark. A generator that won't start is useless. Batteries are perishable; regular checks for voltage, specific gravity, and terminal corrosion, along with timely replacements, are non-negotiable.

- Fuel System Integrity: The Clean Burn. Especially for diesel generators, fuel can degrade over time, leading to contamination and clogged lines. Inspections for leaks, filter replacements, and sometimes "fuel polishing" (removing sediment and water) are vital for a clean, efficient burn.

- Cooling System Vigilance: Preventing Meltdowns. An overheated engine is a dead engine. Checking coolant levels, condition, and inspecting hoses and the radiator ensures proper heat regulation.

- Load Testing: Proving Readiness Under Pressure. This cannot be stressed enough. Running a generator with no load (as in weekly checks) tells you it can run. Load testing tells you it can run when it matters most. It identifies issues that only appear under actual power demand, ensuring the entire system, from engine to ATS, performs as expected.

- Exhaust System: Keeping Things Clear and Safe. Proper exhaust installation, free from leaks and blockages, is critical. It directs dangerous carbon monoxide gases away from people and air intakes. Regular inspections prevent this silent killer from becoming a threat.

Who Should Do The Work? Owner vs. Professional

While the general rule is to follow manufacturer guidelines and use trained personnel, some tasks are suitable for in-house staff, while others absolutely require a certified professional.

Daily Checks: What You Can Handle

Many of the weekly and monthly visual inspections, fluid level checks, and basic operational verifications can often be performed by facility staff who have received basic training. This empowers your team to be the first line of defense, identifying obvious issues like leaks or unusual noises promptly. This daily diligence significantly contributes to the overall reliability of your critical infrastructure.

The Professional Edge: When to Call the Experts

For comprehensive maintenance, including detailed diagnostics, load bank testing, fuel system analysis, complex repairs, and compliance checks, the expertise of trained professionals is indispensable. They have specialized tools, up-to-date knowledge of codes and manufacturer specifications, and the experience to diagnose subtle problems before they become critical.

Commercial generators often require servicing every 200–400 hours of use or at least twice a year. Residential standby generators should be inspected annually, with oil and filter changes every 100–200 hours. Portable generators, often used more intensely, might need service after every 50–100 hours. Always default to the manufacturer's specific recommendations for your model. Investing in a preventative maintenance contract with a reputable service provider is often the most cost-effective approach for critical systems, saving you from much larger expenses down the line.

Safety Above All: Protecting People and Property

Generator safety is not a footnote; it's fundamental. The power and fuel involved present significant hazards if not managed correctly.

Understanding the Risks

- Carbon Monoxide (CO) Poisoning: Engine exhaust contains CO, an odorless, colorless, deadly gas.

- Electrical Shock/Electrocution: Exposed wiring, improper grounding, or contact with live parts.

- Fire Hazards: Fuel leaks, improper storage, or electrical malfunctions.

- Burns: Hot engine components and exhaust systems.

- Mechanical Injuries: Moving parts, belts, and fans.

Core Safety Practices

- Proper Exhaust Installation: Ensure exhaust is directed safely away from building air intakes, windows, and occupied areas. Carbon monoxide detectors are a must in nearby spaces.

- Adequate Ventilation: Generators produce heat and exhaust. The area must be well-ventilated to prevent overheating and the buildup of hazardous gases.

- Cleanliness: Keep the generator area clear of all combustibles, debris, and clutter. A clean environment reduces fire risk and allows for safe access.

- Lockout/Tagout: Before any servicing, disconnect all power sources, including the batteries. Use proper lockout/tagout procedures to prevent accidental starting.

- Proper Grounding: Ensure the generator is correctly grounded according to electrical codes to prevent electrical shock.

- Personal Protective Equipment (PPE): Always use appropriate PPE—gloves, eye protection, hearing protection—when working on or around a running generator.

- Emergency Shut-offs: Know the location and operation of all emergency shut-off switches.

Fuel Storage and Handling

Fuel is highly flammable. Store it according to local regulations, away from ignition sources, and ensure tanks are inspected for damage, corrosion, and proper venting. For diesel fuel, regular monitoring for degradation and water contamination is crucial to prevent system blockages and microbial growth.

Tracking Your Investment: Documentation and Monitoring

A generator maintenance program is only as good as its documentation. Every run hour, every inspection, every repair needs to be meticulously recorded.

The Power of the Log Book

Whether it's a physical log book or an electronic system, documentation allows you to:

- Track Run Hours: Crucial for scheduling time-based maintenance.

- Record Operating Parameters: Monitor trends in oil pressure, coolant temperature, voltage, etc., to spot potential issues early.

- Document Maintenance Activities: Proves compliance, guides future service, and provides a history for troubleshooting.

- Analyze Trends: Deviations from normal operating parameters can indicate developing problems, allowing for predictive maintenance.

Smart Monitoring with Building Automation Systems (BAS)

Many modern critical generators can be integrated into a Building Automation System (BAS). This allows for real-time monitoring of key parameters like run hours, exhaust temperature, fuel rate, and fault codes. BAS integration provides invaluable data for proactive maintenance, often alerting you to issues before they become critical. For those without a BAS, manual monitoring during weekly, monthly, and annual checks, diligently recorded, serves the same purpose of trending and acting on discrepancies.

Decoding the Costs: Budgeting for Uptime

The cost of preventative maintenance is an investment, not an expense. While exact figures vary widely based on generator size, type, and usage, budgeting for routine maintenance is essential. For example, a 300 kW generator operating under 200 hours per year might incur annual maintenance costs ranging from $8,000 to $10,500. This might seem substantial, but it pales in comparison to the cost of emergency repairs, lost business during downtime, or premature generator replacement. Skipping maintenance often leads to increased fuel consumption and reduced efficiency, further inflating operational costs.

Beyond the Checklist: Common Generator Questions Answered

Even with a solid plan, questions arise. Here are some common inquiries about critical generator maintenance and safety:

Q: What's the real difference between standby and emergency generators?

A: Emergency generators are mandated by codes (like NFPA 110 Level 1) for specific life-safety loads where loss of human life is possible (e.g., hospitals, egress lighting). Standby generators (often NFPA 110 Level 2) provide backup for less critical, but still important, loads like business operations or data centers. While both provide backup power, their regulatory requirements, sizing, and design considerations can differ significantly.

Q: How often should I run my generator?

A: Manufacturer guidelines are primary, but weekly no-load runs for several minutes are common to keep seals lubricated and ensure the starting system is functional. Annual full-load testing is critical to verify the entire system's performance under realistic conditions.

Q: Why is load testing so important? Isn't running it enough?

A: Running a generator without a load just proves the engine can start and spin. Load testing (either by transferring the building load or using a resistive load bank) forces the generator to produce its rated power, stressing all components. This reveals issues like voltage regulation problems, cooling system inadequacies, fuel system delivery issues, or exhaust restrictions that wouldn't appear during a no-load run. It's the only true way to confirm readiness.

Q: Can I use car oil in my generator?

A: No. Generator engines, especially diesel and industrial gas engines, have different operating parameters and stress loads than automotive engines. They require specific oils formulated to withstand higher temperatures, different duty cycles, and often have different additive packages. Always use the type and viscosity of oil recommended by the generator manufacturer.

Q: What are signs my generator needs service?

A: Keep an eye out for:

- Unusual noises (knocking, grinding, excessive vibration).

- Visible leaks (oil, fuel, coolant).

- Abnormal exhaust smoke (black, blue, or excessive white smoke).

- Warning lights or error codes on the control panel.

- Difficulty starting or failure to start during a test.

- Fluctuating voltage or frequency during operation.

- Changes in fuel consumption.

Ensuring Your Backup Never Fails: A Call to Action

Your critical generator is a significant investment, a promise of continuity in the face of uncertainty. That promise is only as strong as the preventative maintenance and safety program backing it up. Don't wait for the next power outage to discover your generator's weaknesses. Implement a proactive, comprehensive maintenance plan, meticulously document every action, and prioritize safety above all else.

By embracing diligent upkeep, you're not just maintaining a machine; you're safeguarding your operations, protecting your assets, and ensuring that when the grid goes dark, your vital systems will continue to shine bright. Make the commitment to preventative maintenance today, and guarantee your critical generator's uptime for years to come.